How Are Investment Bars Made

Published on 5 October 2020

Precious metals bars and ingots are one way to invest in possessing physical gold and silver. They are often better preferred to coins because of the closer to the stock market price, more manageable storage, and less risk of imitating.

Although it is easier than minting coins and medals, the production of investment bars is also a long and complex process. By following all the steps a bar has to go through, you will be able to re-evaluate the bars you already own, as well as answer the question of why their price is higher than the stock price of the precious metal.

From the ore to the final investment product

Mining the ore

First, the metal has to be mined. The mining of precious metals is an expensive and laborious process - from the initial geological research to the first real extraction can take an average of between 12 and 15 years. In some cases, even longer, when it comes to a mine that has not been discovered. Gold is mined as the main element available in gold ores and ore deposits, as well as a by-product in the processing of copper ore, etc. Silver is also mined as a primary element in silver mines and as a secondary metal from lead and zinc ores.

Refining

Refining is the next step. This is a process of purification of the metal. The extracted raw material usually has a very poor content of precious metal, often between 7-15 grams per ton. After a flotation process at the place of extraction, the material is significantly enriched to the so-called "doré" and is transported to refineries. There the alloy masses undergo several chemical and physical processes that aim to remove all impurities of other metals. Advanced technologies now allow the purity of the metal to reach 99.99% (fine gold/silver) and even 99.999% (ultra-fine gold/silver). Apart from the production of investment products, gold, and silver of such purity are also used in industry, high technology, healthcare, and almost all spheres of modern life.

Casting, rolling, annealing, punching, polishing

The melting point of 24-carat gold is 1,064.33 °C. Pure silver 999.9 melts at a lower temperature - only 961.93 °C. The casting of metals takes place in specialized vacuum furnaces or furnaces for continuous casting of metals and alloys, which can provide the required temperature.

Let us mention that according to the production technology there are two types of bars - minted and cast. Smaller weights from gold and silver bars are minted from blanks, and larger bars - over 250 or 500 grams to several kilograms, are usually cast. The process of making minted bars largely overlaps with the process of making medals and coins.

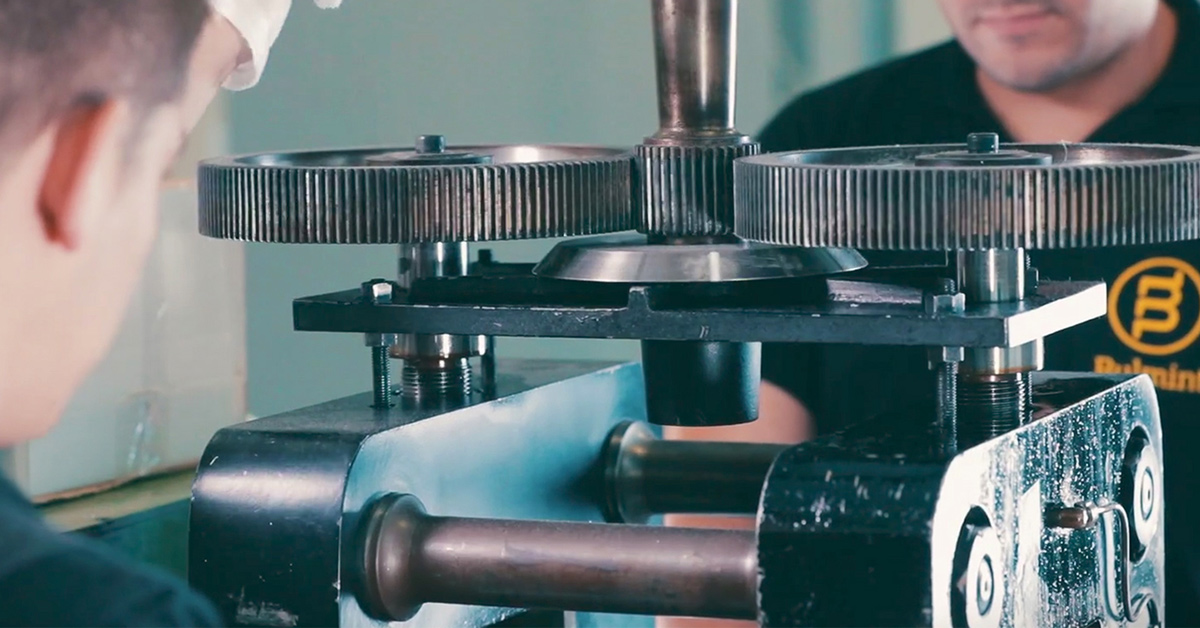

After casting, the metals undergo a rolling process to reach the required thickness of the strips. Annealing is a process in which the strips are reheated to a certain temperature to reduce their hardness. This is necessary for the next stages of processing. The strips should be punched on rectangular blanks with such dimensions as to ensure the required weight of the bar - 20, 50, 100 grams, and again go through the process of annealing, weight checking, polishing, and grading.

For the production of cast bars, the exact amount of molten metal is poured into special graphite molds. After cooling, the finished bars are cleaned and brushed to prepare the surface for the next stage - pressing.

Striking, engraving, and packaging

The striking of the blanks is processed in a high-tech pressing machine with a pressure of 360 tones. Similar to the production of medals, a design for the obverse and reverse side of the bar must be prepared in advance, as well as engraving, hardening, and polishing of the working dies. After striking, each bar is inspected in detail for imperfections, and then engraved with a unique serial number and packed.

Minted vs. Cast Bar

We have already mentioned the bars can be minted or cast. The advantages of minted bars are that the smaller weight is associated with a lower acquisition cost and higher liquidity. On the other hand, the minting technology allows the bar to be struck in the highest proof quality, which is characterized by a mirror glossy surface, exquisite engraving, and high 3D effect of the elements. Thus, in addition to the investment value of the precious metal, the bar also has an aesthetic value. It is these bars that are most frequently preferred as a gift for different occasions - birthdays, anniversaries, graduations, baptism, weddings, and more.

The main advantage of casting technology, as well as the larger weight of the bar, is that it provides a lower and therefore closer to the stock price. These types of bars are the preferred choice for investors who want to acquire a large amount of precious metal at the best price.

What else is good to know?

There are some requirements, for production, engraving, and packaging of the bars, so that the customer is confident in the authenticity and quality of the product.

-

First of all, the content of precious metal must be above 995/1000 for gold and 999/1000 for silver bars. The investment bars produced by Bulmint have the highest purity of the metal - 99.99%.

-

They must be marked on the front of the bar, together with the logo of the manufacturer, the weight of the bar, and the serial number.

-

Bars are marked with a unique serial identification number, which corresponds to the number indicated in the certificate.

-

All traders of currency and precious metals in Bulgaria must be registered under Art.13 of the Currency Act. The register is public and you can easily access it here.

-

For gold bars, the packaging is extremely important. It is their certificate of quality and for this purpose must be specially designed to contain information about the manufacturer, weight, purity, and the serial number of the bar.

-

The silver bars are placed in a capsule or vacuum bag so that they do not come into direct contact with the air. It is recommended to store them in places with low or no humidity to prevent tarnishing.

If you are looking to buy 0.999 fine gold or silver bars, you can discover more options in the Investment Bars category.