How Are Unique Silver Medals Made

Published on 18 October 2019

Silver is one of the first metals documented in history found in nugget form around 4000 BC. Interestingly, silver has been used as currency more than any other metal.

Today, only a small amount of silver is used in coin production, usually for coins and medals in the highest proof quality. Apart from the collectors and numismatic worth of the medals, they possess investment value as well.

The concept of the collection

Making a unique silver medal is a long process that begins with the concept of the collection. This is very important, especially with commemorative collections, as each motif has to be meaningfully and compositionally subordinated to the basic artistic idea.

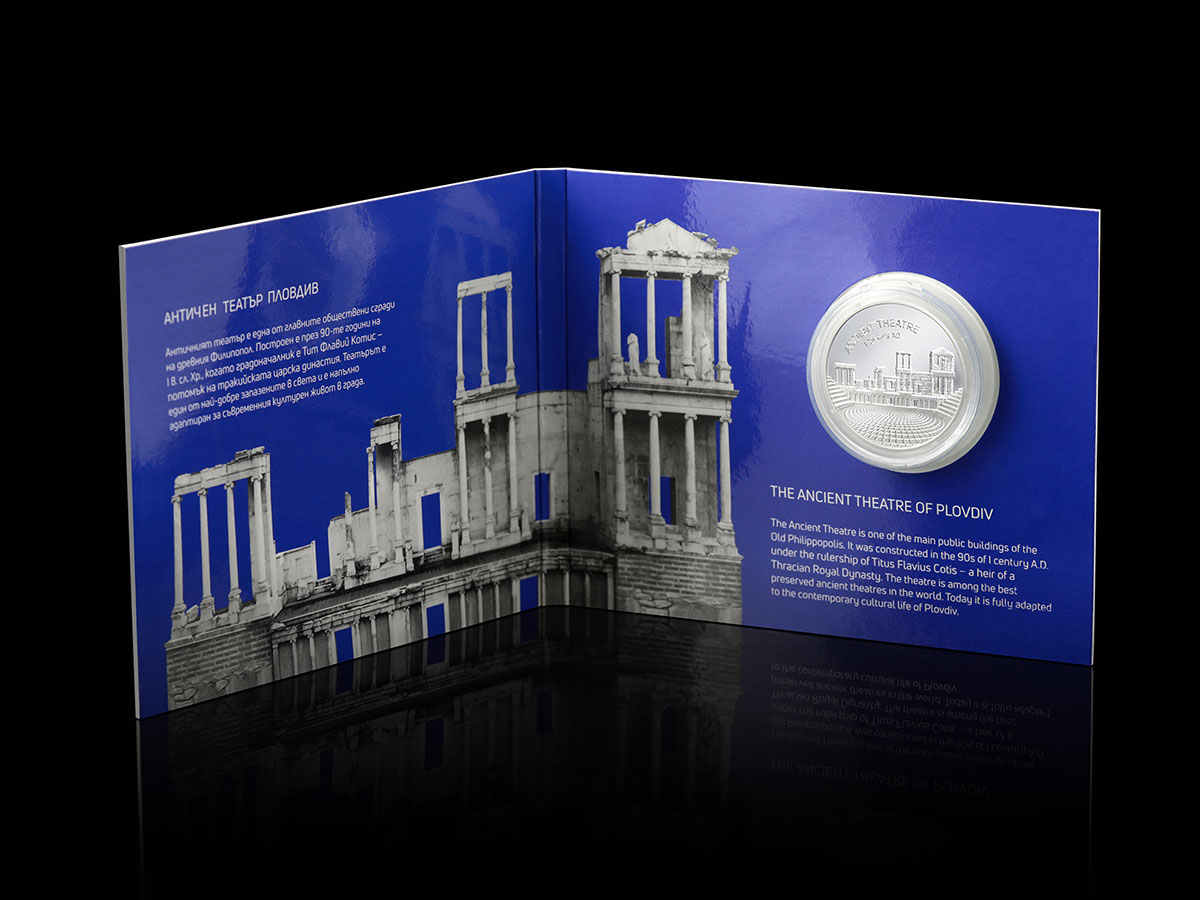

When we talk about collections, the reverse is always the same - for example, the reverse of all the medals from the #together collection is the logo of Plovdiv European Capital of Culture 2019. The obverses present different motives - in our case, the most remarkable and well-known architectural and cultural monuments of Plovdiv.

The graphic project

The production itself starts with the graphic design of the obverse and the reverse of the medal. On that basis, a plastic model is made, and after that a plaster cast. Then the plaster cast is digitized and further processed to provide greater detail and clear relief.

Only 10 years ago, the technologies for turning plastic models into a working die were much less sophisticated, and therefore the possibilities for the implementation of artistic projects more limited. Modern digital technologies allow extremely wide possibilities for creating and processing almost any kind of art project with incredible precision and detailed perfection.

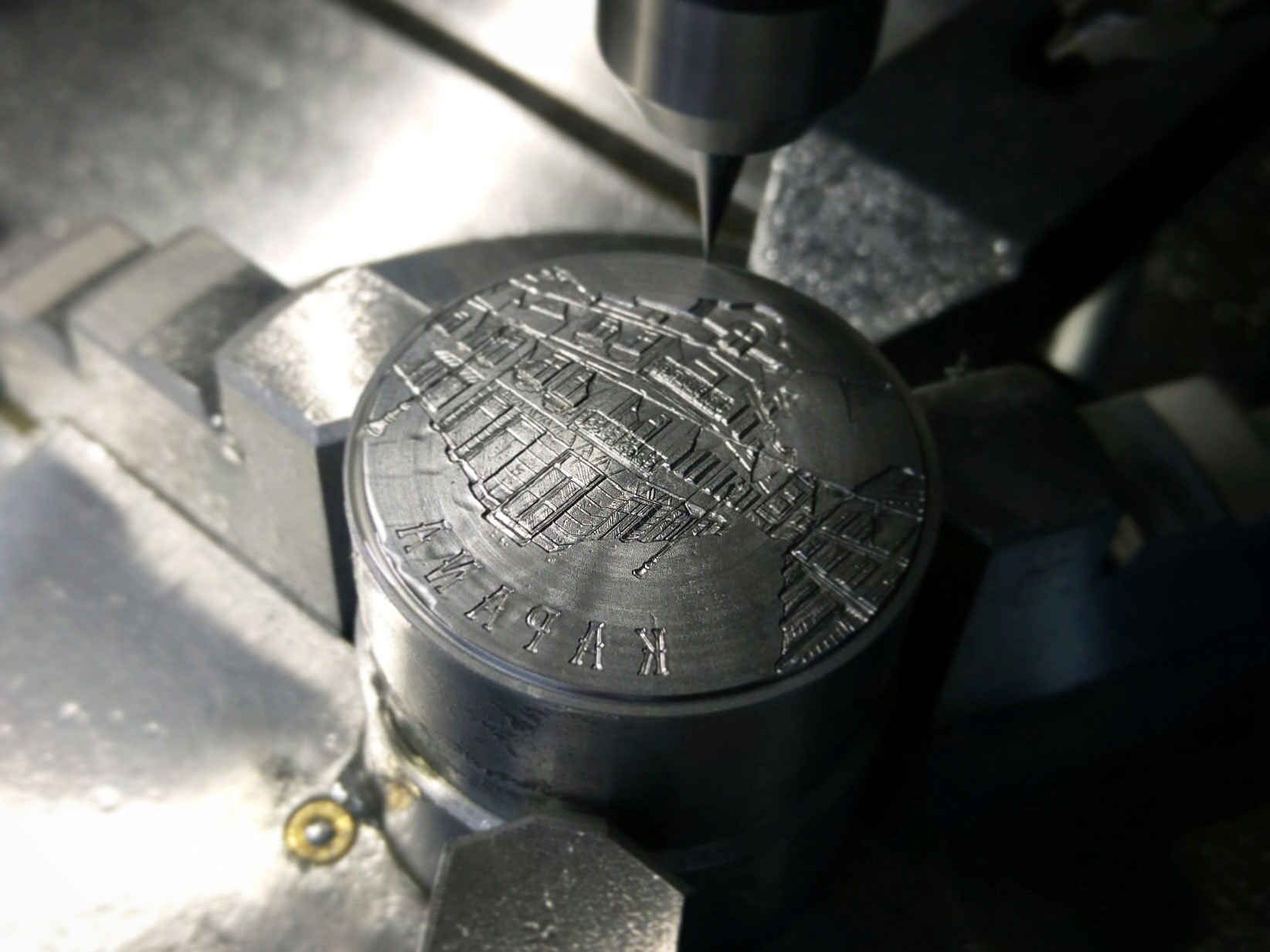

Engraving of the working die

Once the 3D image is complete, the process proceeds with engraving the working die, which will be used to stamp the medals. A working die is a tool made of special steel, which contains a negative of the design that is stamped on the medal. Accordingly, working tools are prepared separately for the obverse and reverse side of the medal. Depending on the size and complexity of the project, engraving the negative of the design can take anywhere from several hours to several days.

Once engraved, the working die is refined by hand to achieve the highest cutting quality and maximum relief detail. The next steps are tempering and complete surface preparation, which results in manual polishing and frosting. This stage is extremely important, and a lot of time and work is invested in it because it guarantees the contrasting mat-gloss finish when cutting off a medal in proof quality.

Silver Blanks Production

At the same time with the engraving of the tool, the producing of the silver coin blanks begins. This process is equally important and goes through several different phases. The first phase is melting and pouring silver into a silver billet. This billet is then put in an extruder machine, which elongates the strips of metal. The final thickness is adjusted up to а hundredth of the millimeter. During the extruding process, the 925 silver goes through several stages of recrystallization through specially made tunnel furnaces. The purpose is to prevent the alloy from hardening during the extruding process.

The silver strip then is cut into round blanks of exact diameter and weight, which subsequently undergo several chemical and surface treatment stages to produce a mirror finish - something extremely important for obtaining a proof medal.

Pressing

Each silver blank is individually fed into a high-tech pressing machine and stamped with a pressure of 360 tones. After the stamping, each medal is inspected in detail for imperfections of the embossed surface and the engraving. Every product that has undergone this verification is considered a proof medal.

Did you know that silver is the most reflective element? It can reflect up to 95 percent of the visible spectrum light. That is one of the reasons why it was chosen as a material for stamping the #together medals. Due to this and because of the specific minting process, that proof silver medals are easily distinguished by their mirror gloss, the frosted finish of relief and exquisite detailing.

Packaging

The long production process ends with placing the medals into storage capsules, designed to protect them from external conditions and mechanical scratches. After that, they are placed in the final package or box, which also follows the idea and design of the collection.

An interesting fact about proof medals is that throughout the entire production process, silver medals are never touched with bare hands. Gloves are always used for all activities that require human intervention and manual labor.

It is common for proof medals to be minted in small limited series. Even then a lot of work and attention to detail are required even for manufacturing. Therefore, along with the value of the precious metal, silver medals in proof quality provide their owners with significant added value.